Case studies

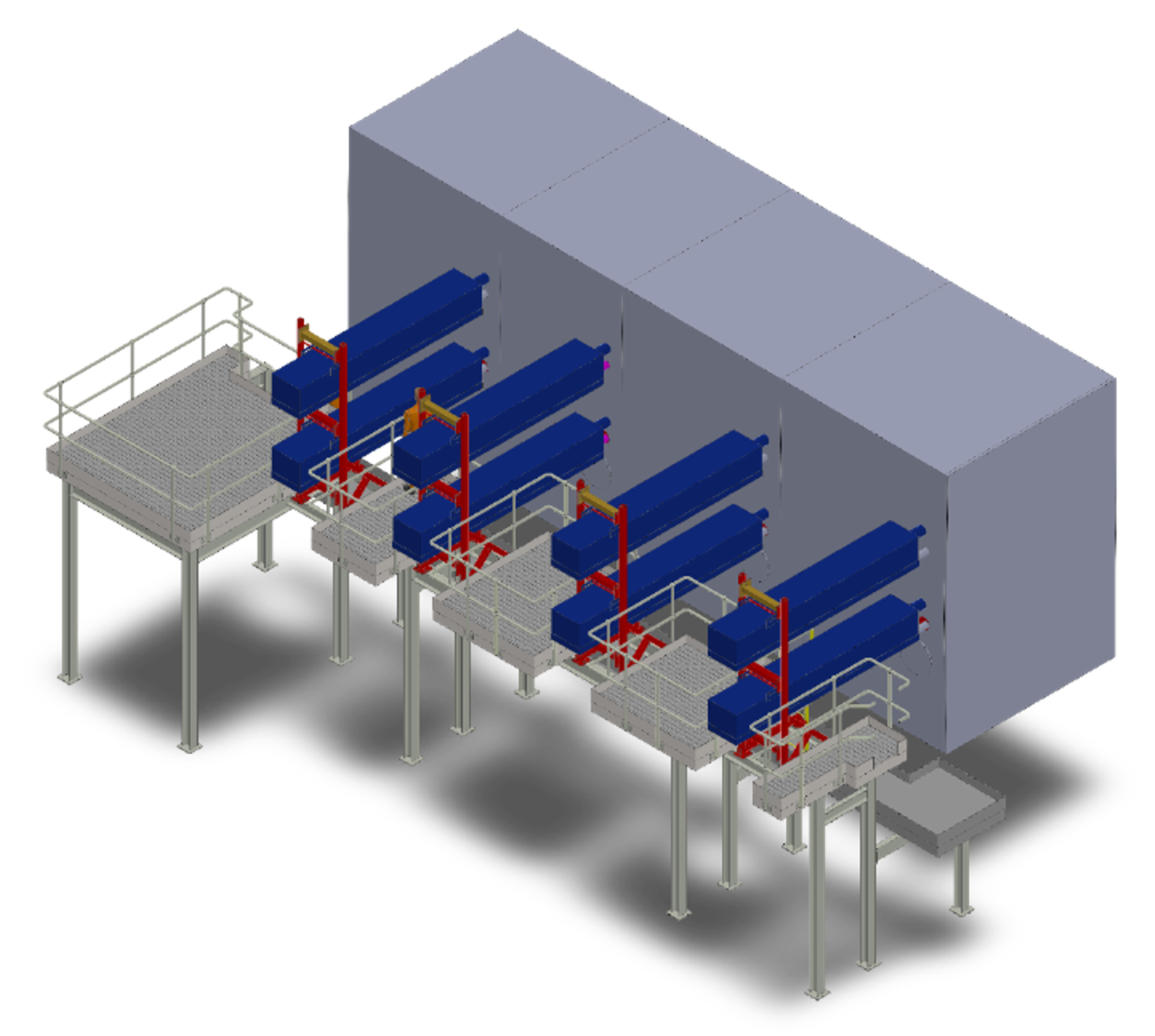

Shock Pulse Generator

Gasification Plant

Client: Full Circle Generation

Location: Belfast

Background

Throughput: 160 tpa RDF

Thermal Output: 14.85 MW

Boiler Lines: 3

Plant Supplier: Changsha Boiler Plant Co.

Operator: Full Circle Generation

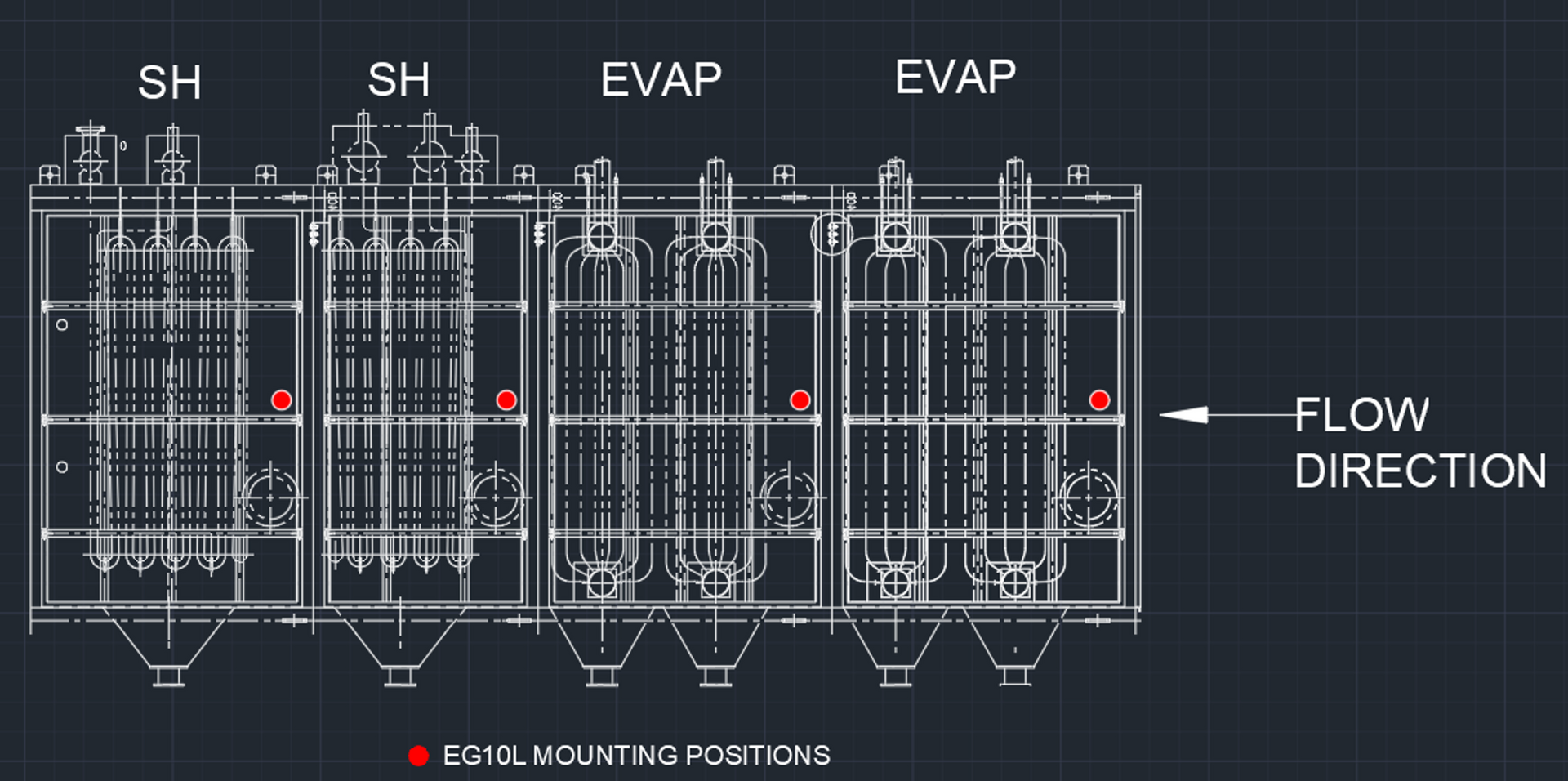

Boiler configuration:

- Each line features a horizontal pass with 2 vertical EVAP/Screen bundles and 2 vertical SH bundles.

Challenge

Following plant commissioning, the site experienced significant slagging and fouling across the bundle sections and hoppers. This led to restricted operation cycles, requiring weekly manual detonation cleaning and limiting continuous operation to around 4 weeks.

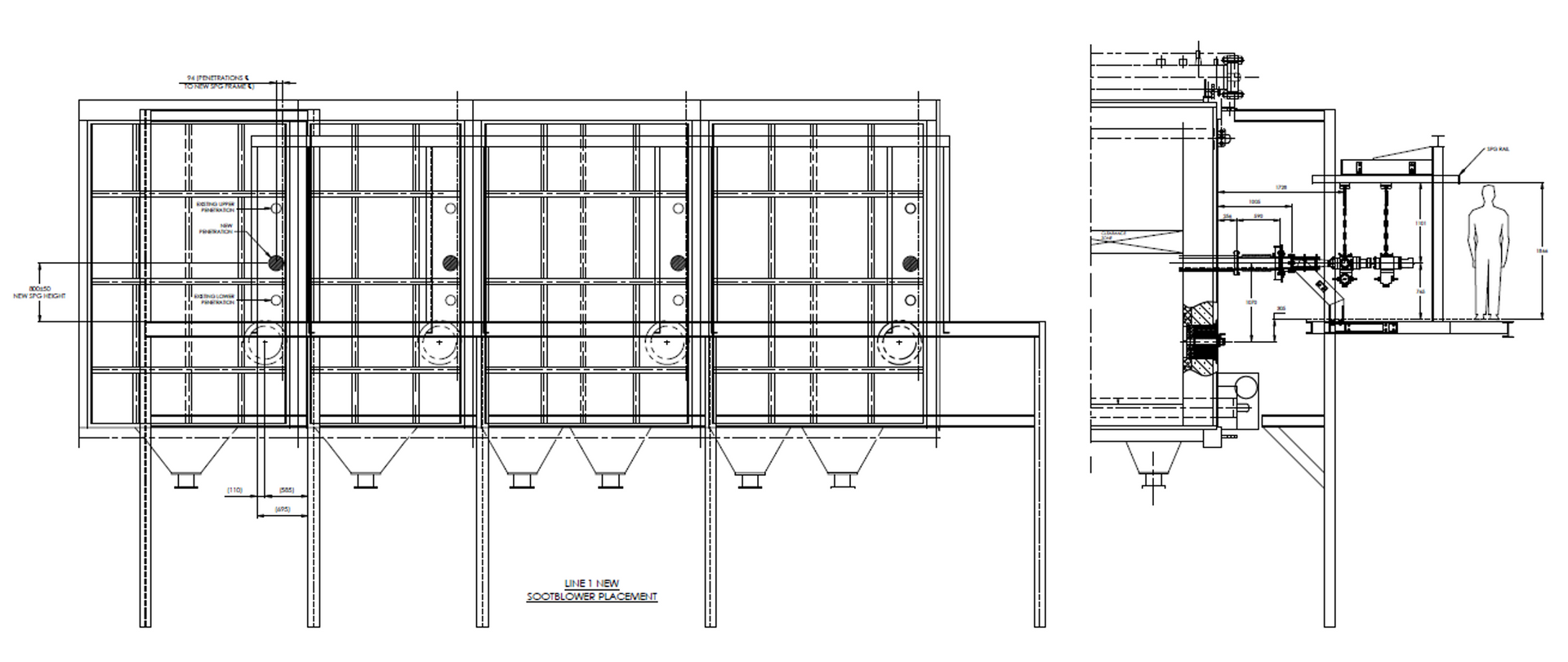

Initial Setup

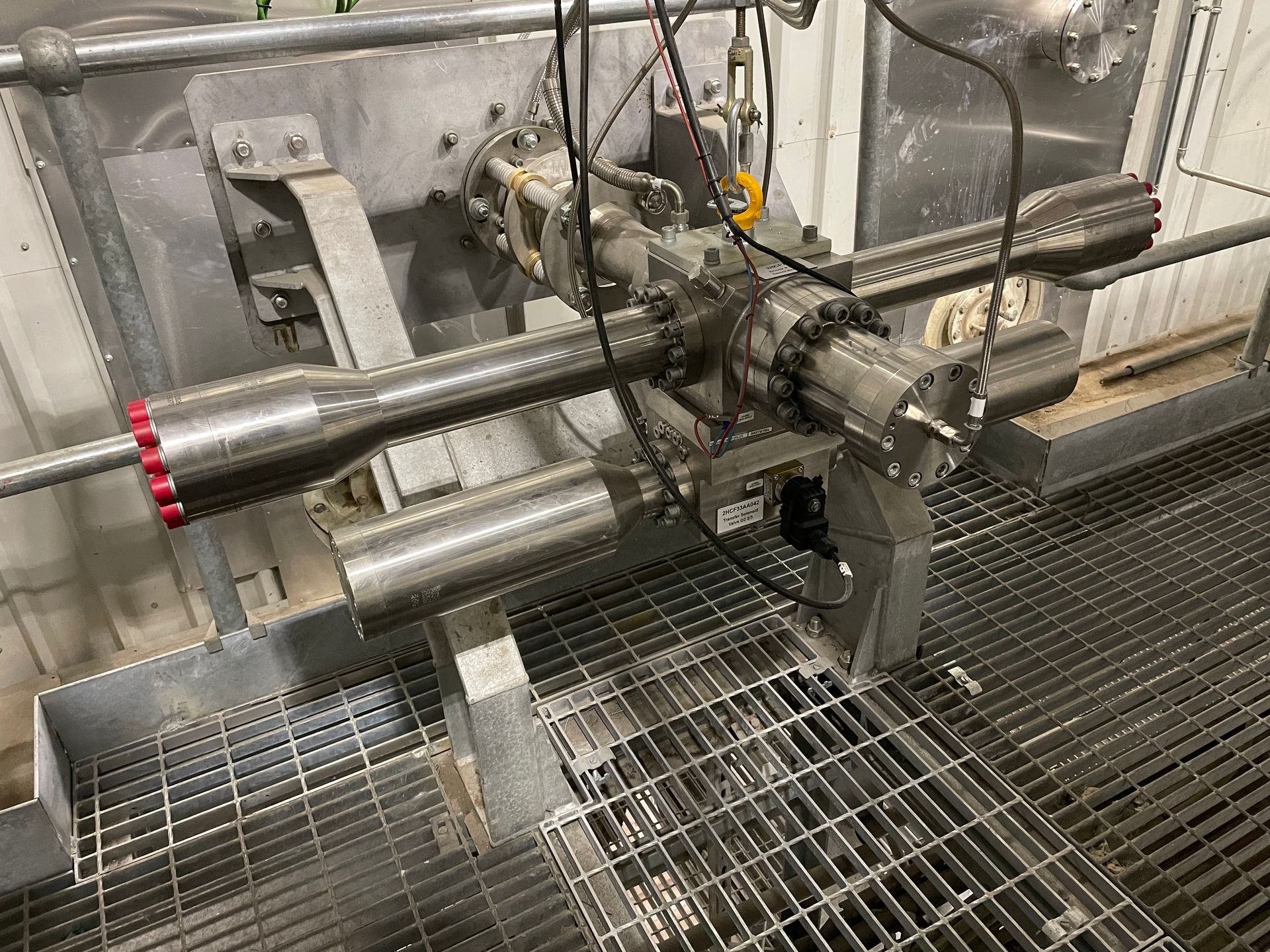

In 2021, each boiler line was fitted with 3 KRR ProStream SPG units, while 2 conventional sootblowers remained in place. High-temperature camera surveys demonstrated the effectiveness of SPGs, and the remaining sootblowers were replaced during the next shutdown in 2022.

Current Configuration

All 8 sootblowers per line have now been fully replaced with 4 KRR ProStream EG10L SPG units per boiler line.

Results

Since installation, the SPG system has significantly reduced fouling within the heat exchange bundles, enabling the plant to operate at full load for up to 6 months between planned outages (not fouling-related). Manual detonation cleaning is now only carried out on an ad hoc basis in areas not directly covered by the SPGs.

Hopper sections and interconnecting shelves have also remained generally clear, further supporting efficient, continuous plant operation.

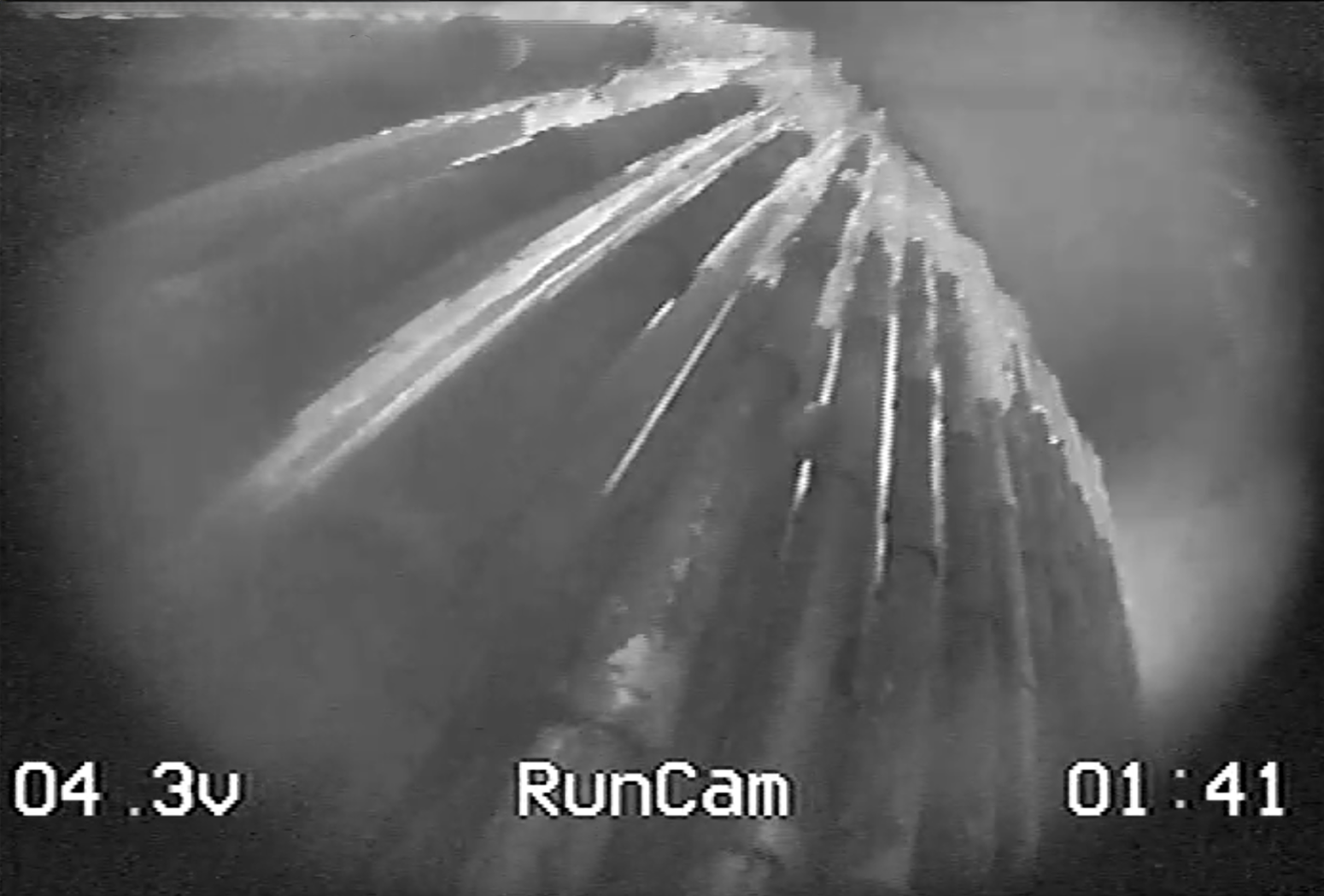

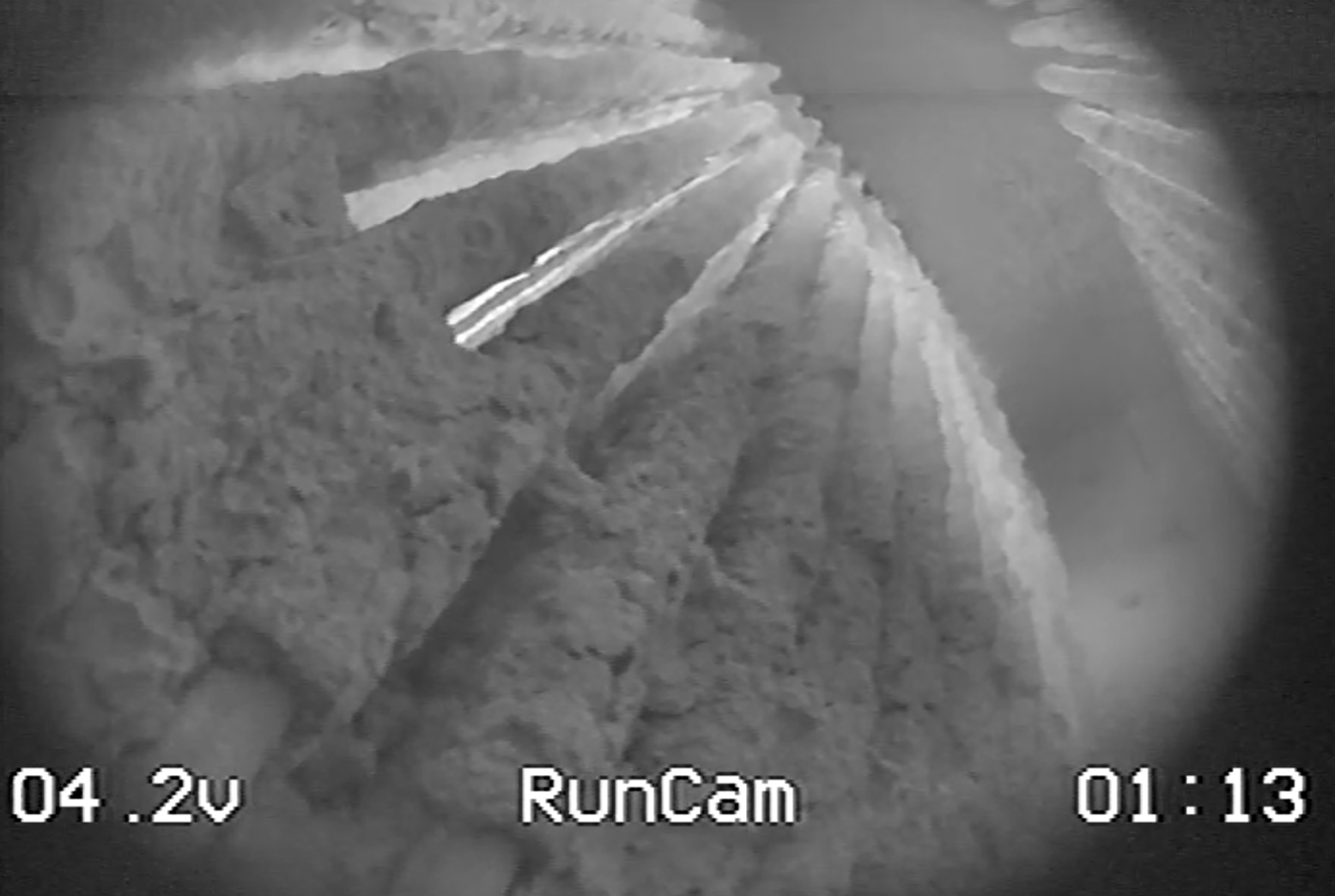

Below: High temperature video camera survey after approx. 8 months of boiler operation.

SH location with sootblower operation:

SH location with SPG operation: