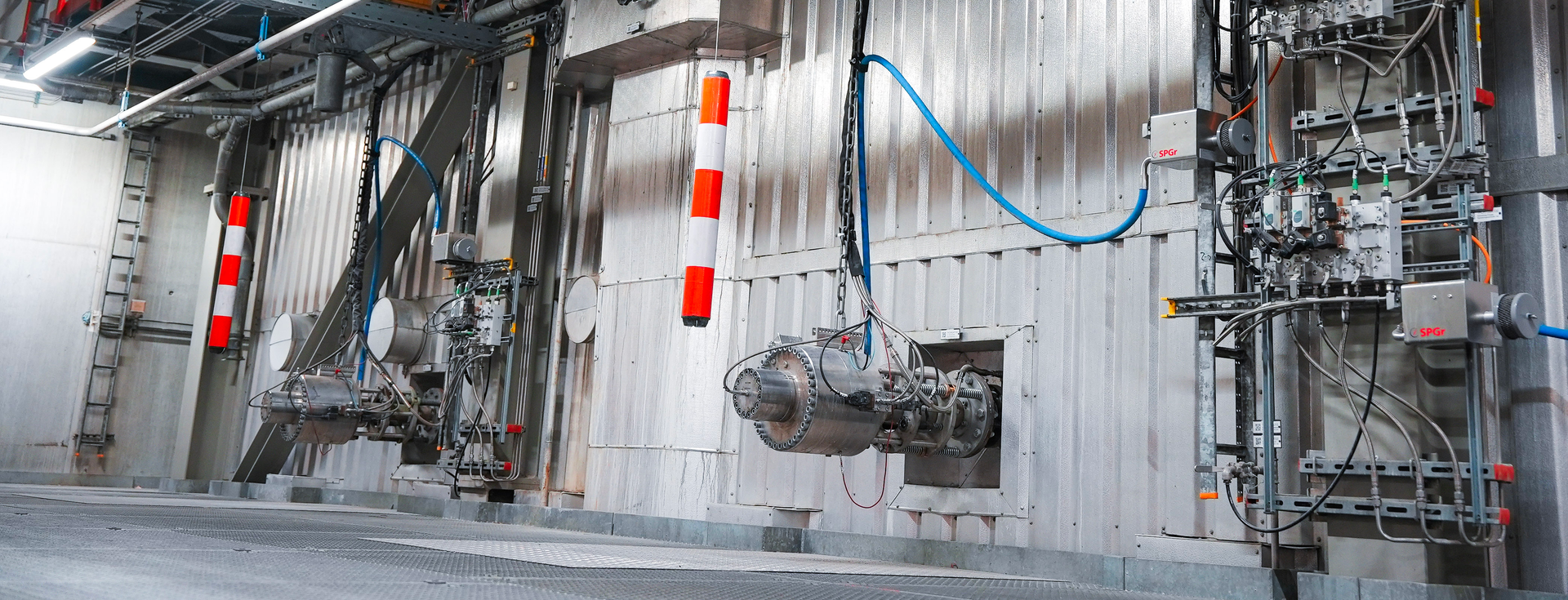

INSTALLED & AUTOMATED SYSTEM

Shock Pulse Generators

Efficient boiler cleaning with Shock Pulse Generators

With proven online cleaning technology, deposits on heat exchanger surfaces, e.g. membrane walls and tube bundles, can be successfully prevented in large boiler plants. In retrofit projects, the deposits can be significantly reduced. This innovative Shock Pulse Technology enables you to achieve longer operating periods, higher boiler availability and a reduction in maintenance and operating costs.

More than 1,000 installed Shock Pulse Generators (SPG) are keeping critical boiler areas permanently clean, for multiple fuels like municipal solid waste, industrial waste and coal, as well as in process plants. Waste, industrial, coal-fired power plants and process plants permanently clean.

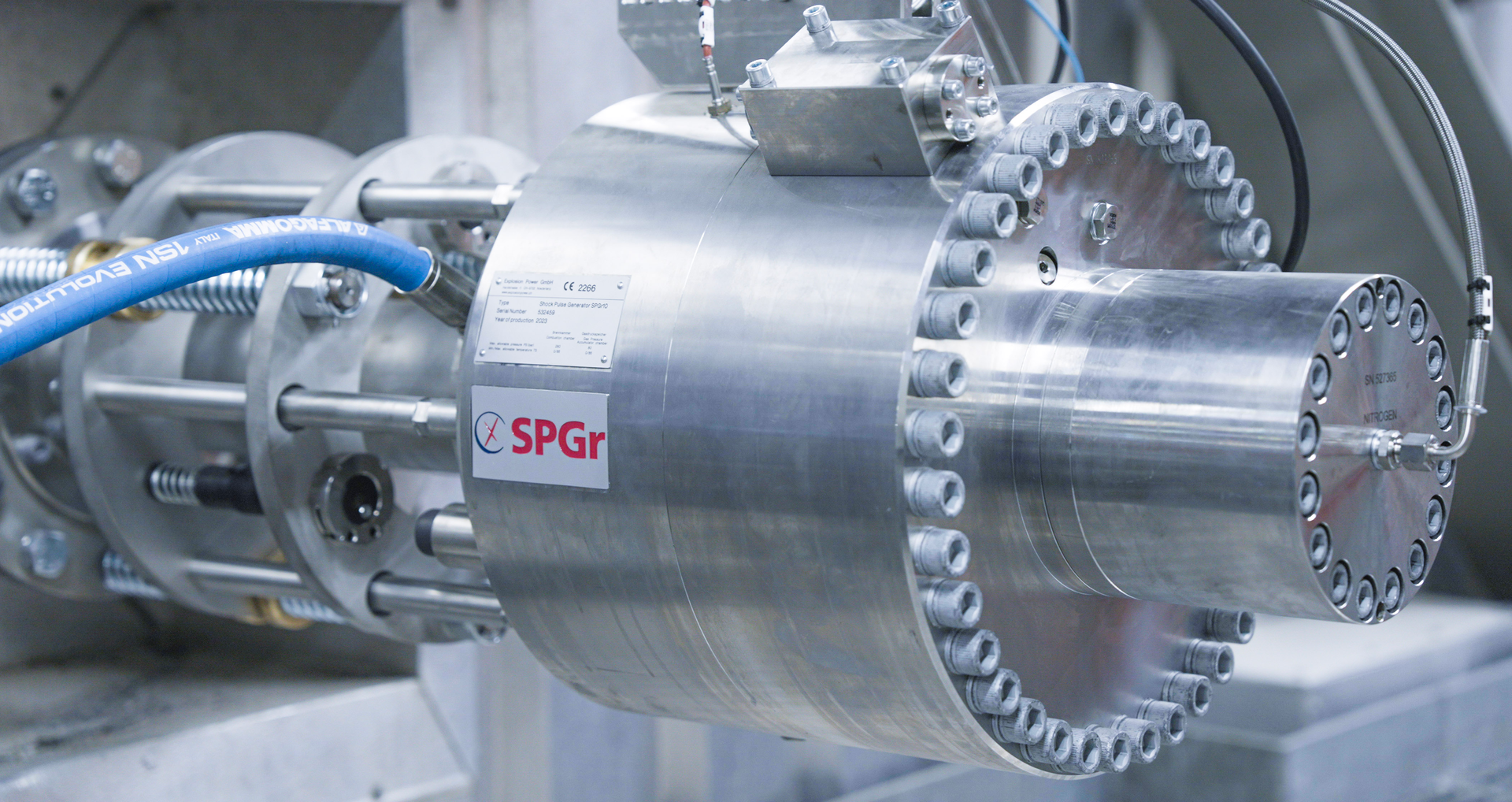

SPG technology

The Shock Pulse Generator (SPG), developed and manufactured by Swiss company Explosion Power GmbH, is an online boiler cleaning equipment automatically generating Shock Pulses (SP) by pressurised gas combustion. The innovative technology has proven its outstanding performance at worldwide with over 1,000 different installations in 20+ countries since 2009. Plant operators confirmed significant prolongation of boiler operating periods and increased efficiency, thus contributing to a sustainable and economic plant operation. Leading plant suppliers decided to apply SPG-technology to new build plants, additionally profiting from the sophisticated system design and the compact geometry.

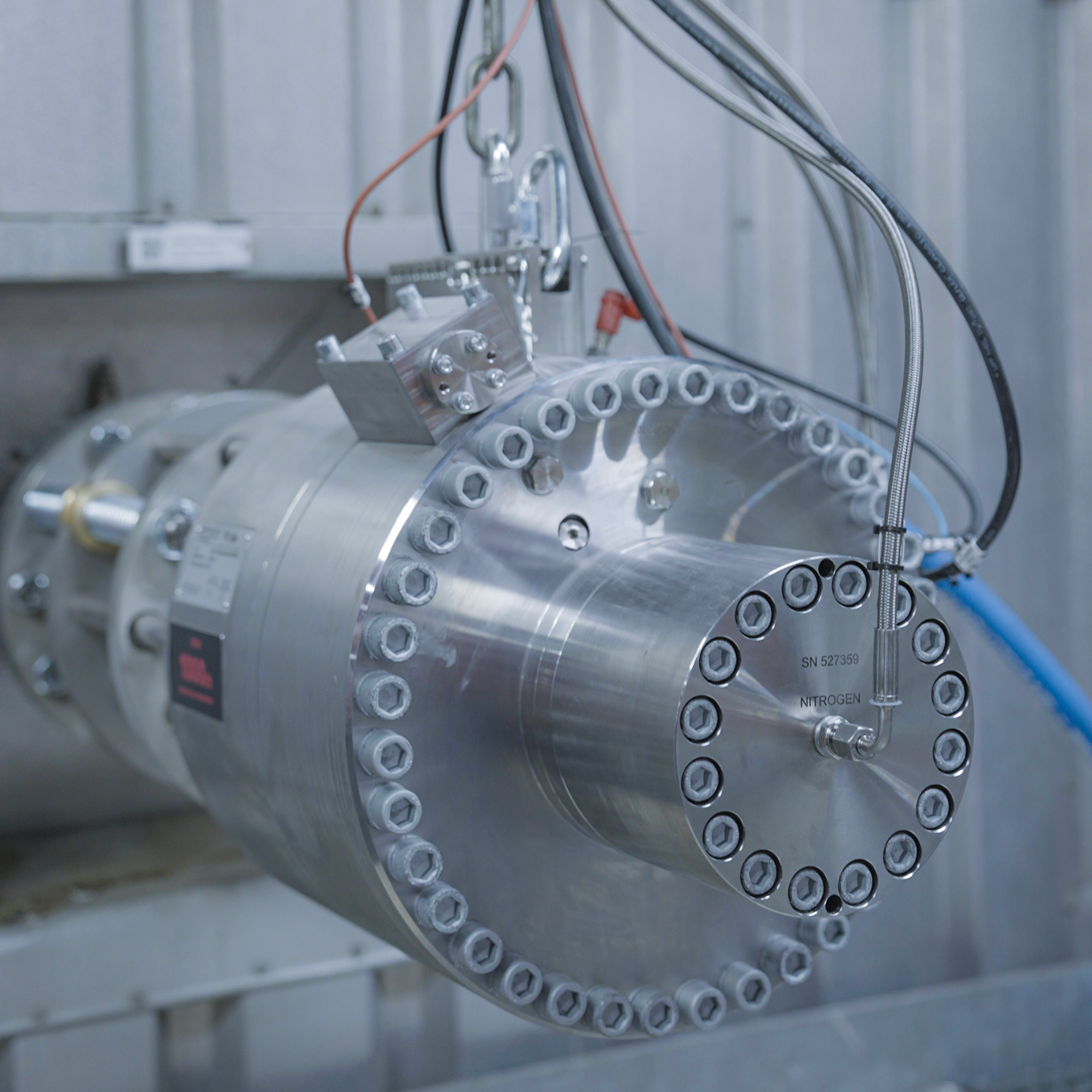

SPGr-series

Our product series, the Shock Pulse Generator SPGr, revolutionises automated industrial boiler cleaning. The innovative further development of existing technology enables even higher cleaning performance with reduced maintenance and space requirements. This effectively meets customer requirements for high plant efficiency and sustainability.

Consulting

- Expert advice based on years of experience

- Over 1,000 Shock Pulse Generators increase profitability in more than 250 plants worldwide

- Continued project support extended beyond commissioning

High-quality boiler cleaning

Continuous boiler cleaning

- Standardised Shock Pulse Generators with robust and innovative technology

- Forward-looking and clear maintenance concept

- Lower flue gas temperatures, reduced pressure losses due to automated boiler cleaning

Efficient and stable plant operation

Data analysis & status overview

- Analysis of the operating status of the Shock Pulse Generator

- Status overview enables fast and efficient support and maintenance diagnostics

- Status overview enables fast and efficient support and maintenance diagnostics

Reliable device operation

Optimisation of boiler operation

- Analysis of boiler operational data

- Optimisation of boiler operation based on the gathered data and insights

- Clearly demonstrate the impact on boiler operation

- Extension of boiler operation period

- Customised recommendations for intensity level settings for optimal SPG operation

Increased plant efficiency and profitability

Shock Pulse Generators at a glance

- Permanent and automated boiler cleaning, thus lower exhaust temperature and higher boiler efficiency, improved CO2 plant performance

- No steam consumption, no thermal abrasion or damaging of boiler tubes

- High degree of operational safety – boiler remains closed during operation

- Fast and efficient support and maintenance diagnostics

If you have any questions or wish to discuss your requirements: