INSTALLED & AUTOMATED SYSTEM

SC-Jet Shower Cleaning

The clean way to clean boilers

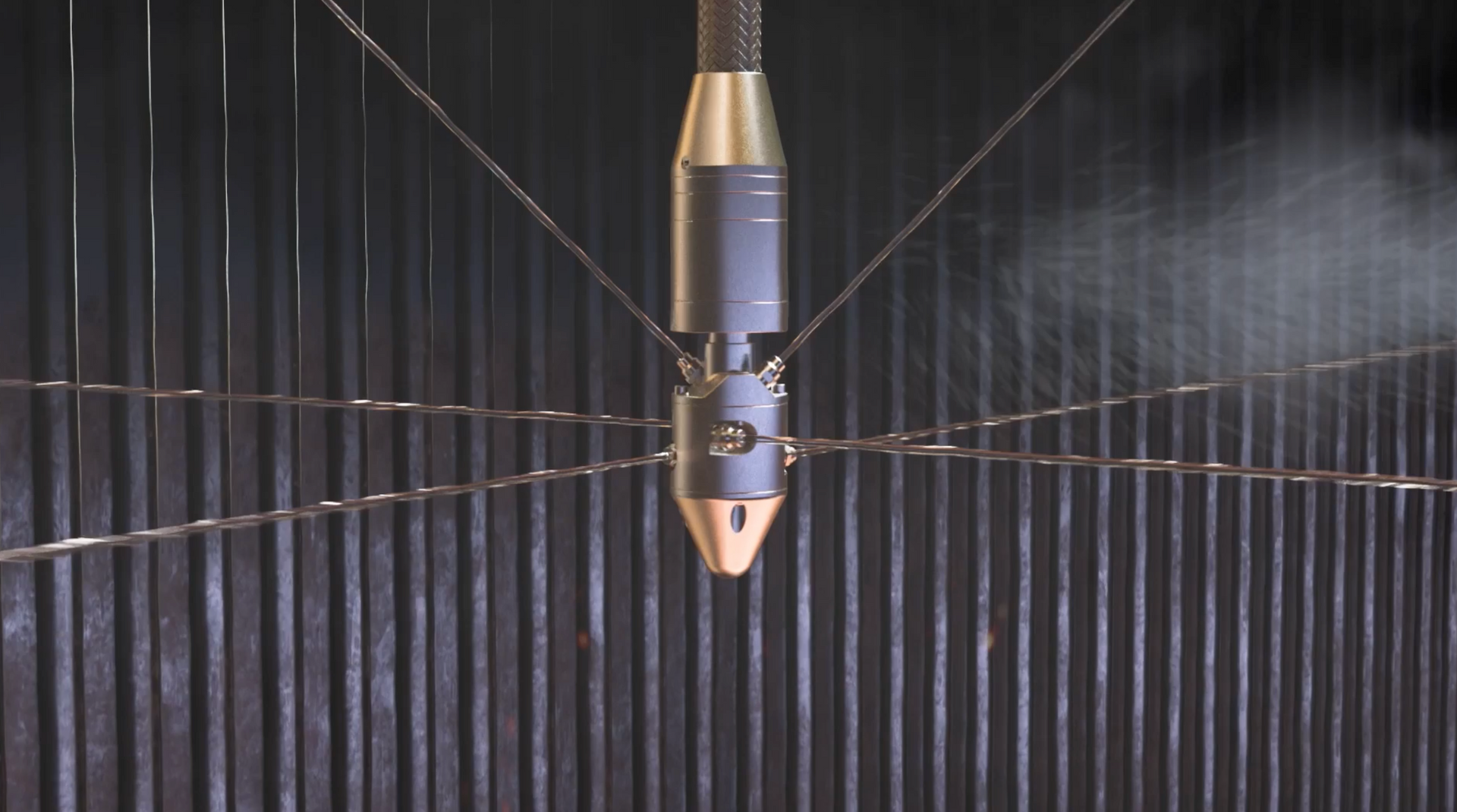

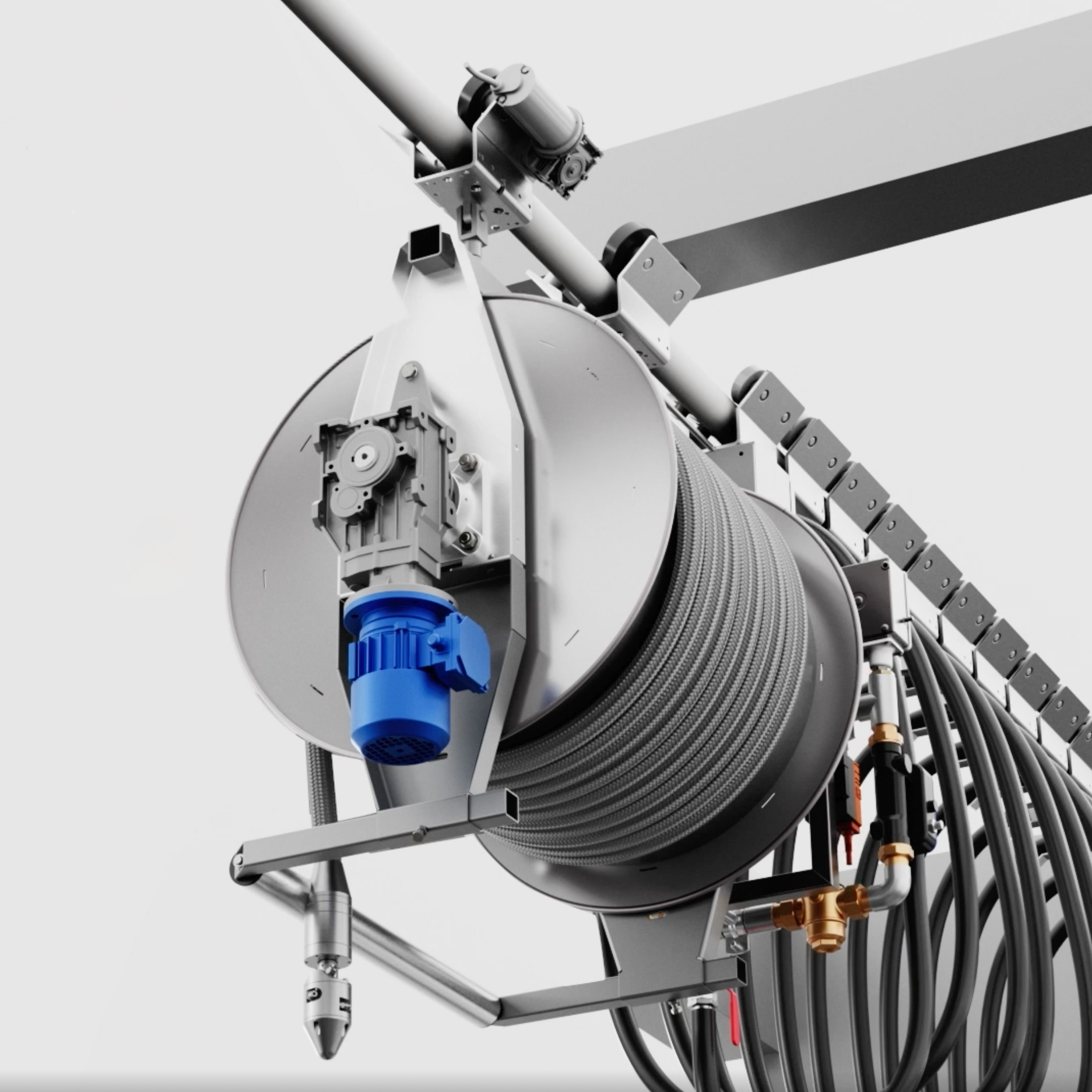

The Aerovit SC-Jet shower cleaning solution is a unique rotating nozzle head that sends concentrated water jets more than 5m on to the heating surfaces for cleaning the boiler during full-load operation of the incinerator.

The Aerovit SC-Jet system operates at high temperatures normally seen in the first and second passes in waste-to-energy plants (600-1250°C). The operation can be supervised from the control room and is 100% automatic. The injection into the boiler through the roof is automatic and controlled by a PLC system, executing an individually defined cleaning sequence for each injection hole. Normally it will reduce the flue gas temperature at the radiation boiler outlet with 60˚C and increase the boiler efficiency.

Due to the design of the Aerovit SC-Jet, the nozzle is capable of sending four to six concentrated water jets more than 5 metres on to the heating surfaces which minimises the number of inlets through the boiler roof.

Please get in touch to arrange a site visit to discuss your cleaning requirements.

Here's how it works

SC-Jet Shower Cleaning at a glance

- Increased boiler efficiency 3-5%

- Reduction of flue gas temperature at the radiation boiler outlet with 50-80˚C

- Water jets that sprays more than 5 metres

- Minimum inlets through the boiler roof