CLEANING & MAINTENANCE SERVICES

Filter Bag Cleaning Technology

The challenge

The pulse air systems on filter bags are typically designed to remove excess Air Pollution Control (APC) cake from around the bags. However, the pulse air system effectiveness reduces over time due to ingrained dust clogging the bag filter material, causing pressure drops that affect the commercial operation of the boiler and result in filter bags being replaced at a significant cost.

Our solution

KRR ProStream's Filter Bag Cleaning Technology can deliver cost savings in as little as 6-months from the operational efficiencies. Deep cleaning of the individual bags to an ‘as new’ condition, significantly reduces the frequency of bag replacement and the service can be undertaken with the unit in operation (n+1) or as part of a planned shutdown.

Monitoring service

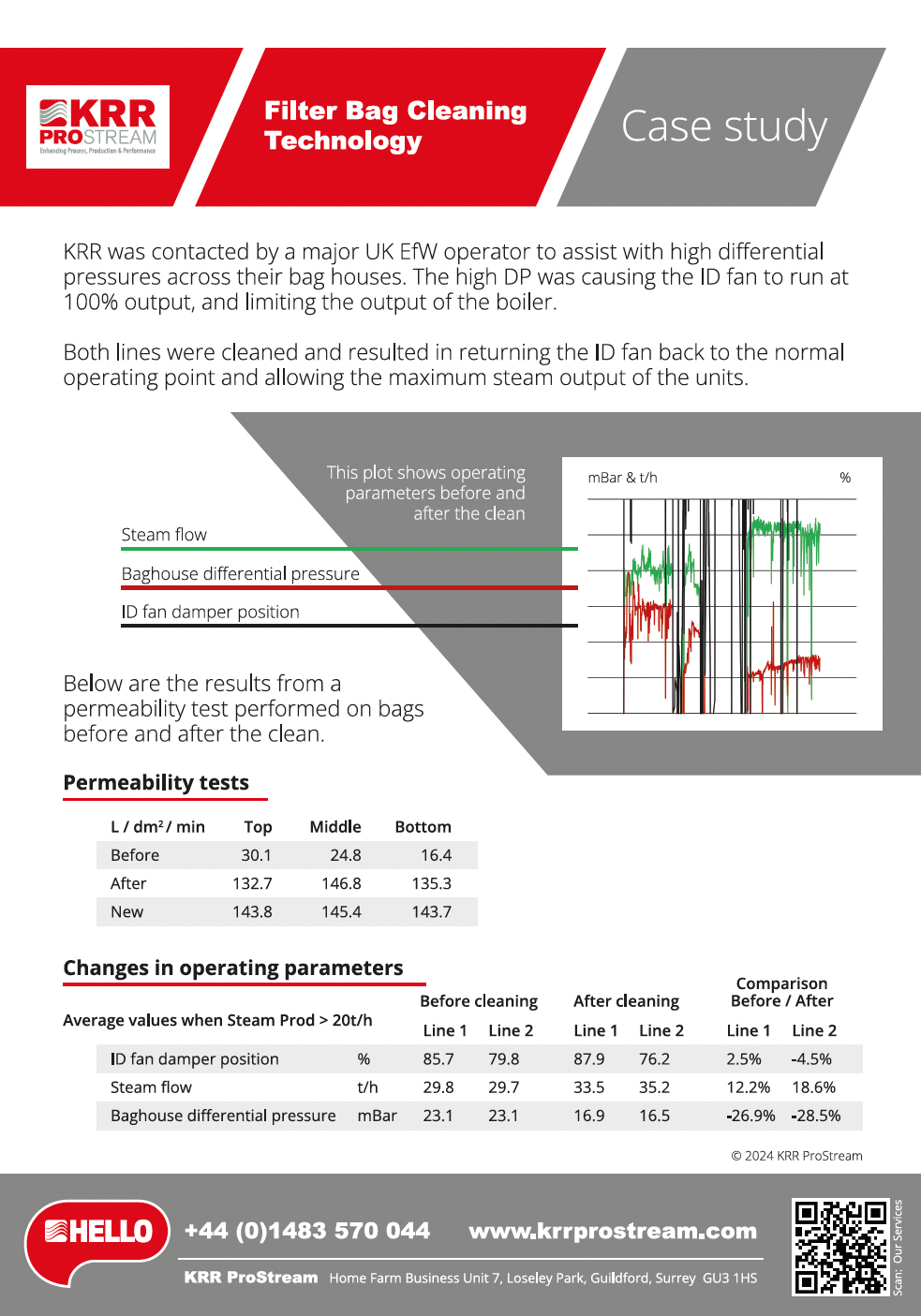

We test the permeability of each ‘whole bag’ without the need to remove them, providing key performance insight to the operator, enabling a highly optimised and efficient cleaning schedule. Using this test data, in conjunction with operational data of the whole baghouse, the operator is able to achieve:

- Improved forecasting of filter bag life

- Extended bag life and decreased capital expenditure

KRR ProStream's site personnel are highly experienced with the expected competencies, supported by our technical resources. All work is undertaken to expected safety standards under ISO 45001 (Occupational Health and Safety Management System).

Filter Bag Cleaning Technology at a glance

Save time, money and improve plant performance with regular filter bag cleaning:

- Save money by extending operating life of existing filter bags

- Reduce pressure drop and maximise plant output

- Maintain profit; no need to come offline during cleaning operation