Case studies

Shock Pulse Generator

Vertical Pass

Client: REAL Luzern

Location: Lucern, Switzerland

Background

Vertical Pass – WtE Lucerne, B3 / Switzerland.

Steam Capacity: 17 t/h

Plant Supplier: Von Roll (HZI)

System Overview

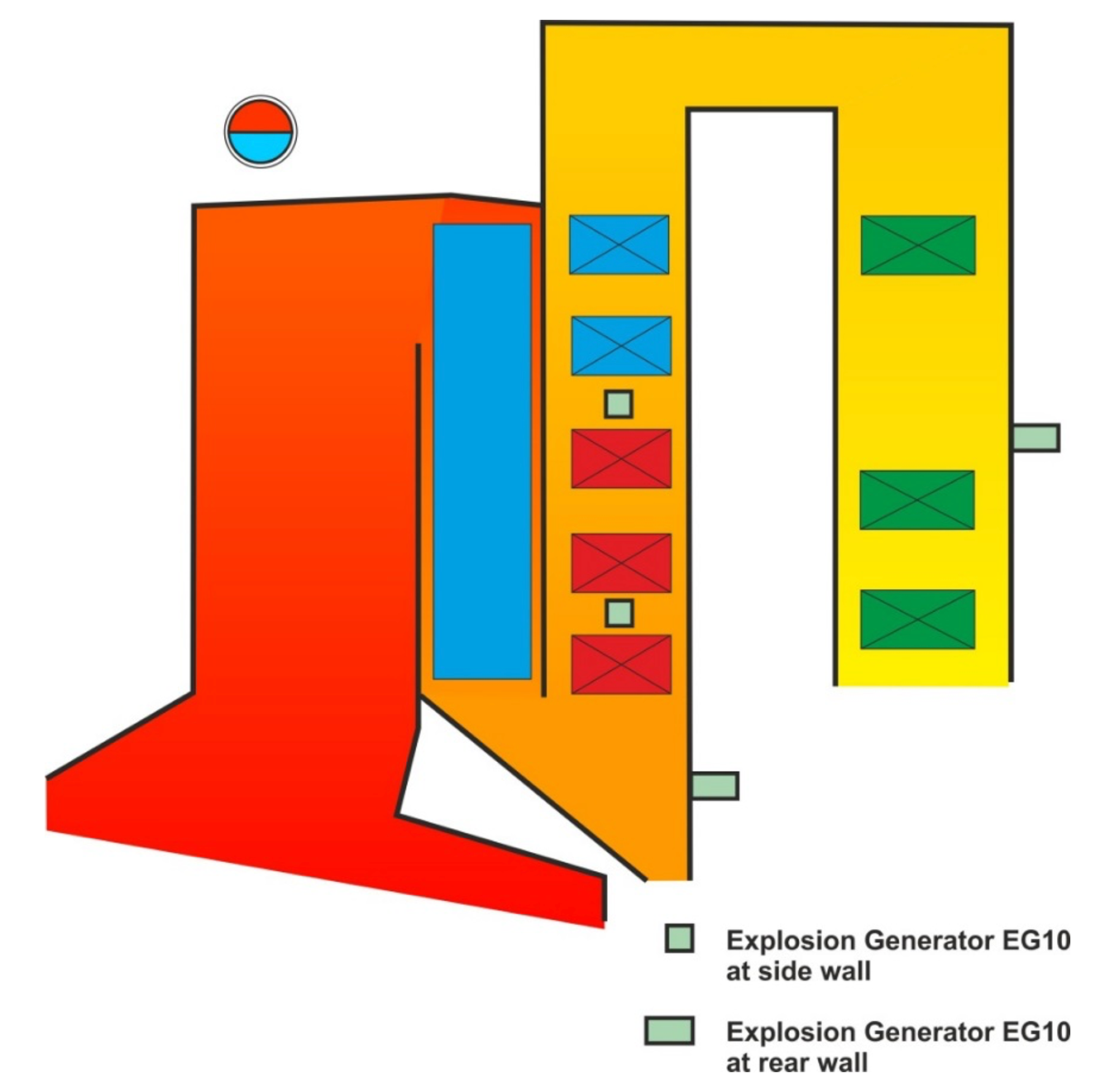

2nd Pass

Dimensions: W 3.1 m x L 1.6 m

- Includes 4 panel evaporators, pitch 600 mm

- Cleaned by 1 EG located in the 3rd pass since November 2009

- Replaced manual explosion cleanings previously required every 2–4 months

3rd Pass

Dimensions:

W 3.1 m x L 2.1 m

- Bundle configuration: Pitch H/V / Tube Ø / Bundle height:

- EVAP1: 125/80/31.8 mm; 1.0 m

- EVAP2: 125/80/31.8 mm; 1.0 m

- PSH1: 125/80/31.8 mm; 1.0 m

- PSH2: 125/80/31.8 mm; 1.0 m

- FSH: 150/80/31.8 mm; 1.0 m

- 2 SPG units installed since June 2009, replacing 8 sootblowers

4th Pass

Dimensions: W 3.1 m x L 1.9 m

- Pitch H/V: 80/80; Tube Ø: 31.8 mm

- Bundle heights: 1.3 / 1.5 / 1.6 m

- 1 SPG installed since February 2010, replacing a shot ball system

Conclusion / Performance

Cleaning Effect: Very good

Significant improvements in boiler operating and maintenance costs.

Lucerne – All 3 Boilers:

SPG units were the sole cleaning equipment for over 5 years, performing more than 500,000 shock pulses - well beyond typical operational requirements.

Note: Site also served as an EP test plant.