Case studies

Shock Pulse Generator

CNIM Boiler

Client: FCC Environment

Location: Lincolnshire

Overview

Faced with operational challenges from increased throughput and persistent boiler fouling, FCC Environment turned to KRR ProStream’s SPG (Shock Pulse Generator) technology to stabilise performance, reduce cleaning intervention, and extend uptime.

- Steam Flow: 68 tonnes per hour

- Steam Conditions: 58 bar, 400°C

- Waste Throughput: 190,000 tonnes per annum (original design: 150,000 tpa)

Background

FCC Environment’s high-throughput waste-to-energy facility, originally designed for 150,000 tpa, had increased input to 190,000 tpa. This increase pushed the plant to its limits, with boiler fouling leading to cleaning challenges, increased maintenance, and near-miss shutdowns.

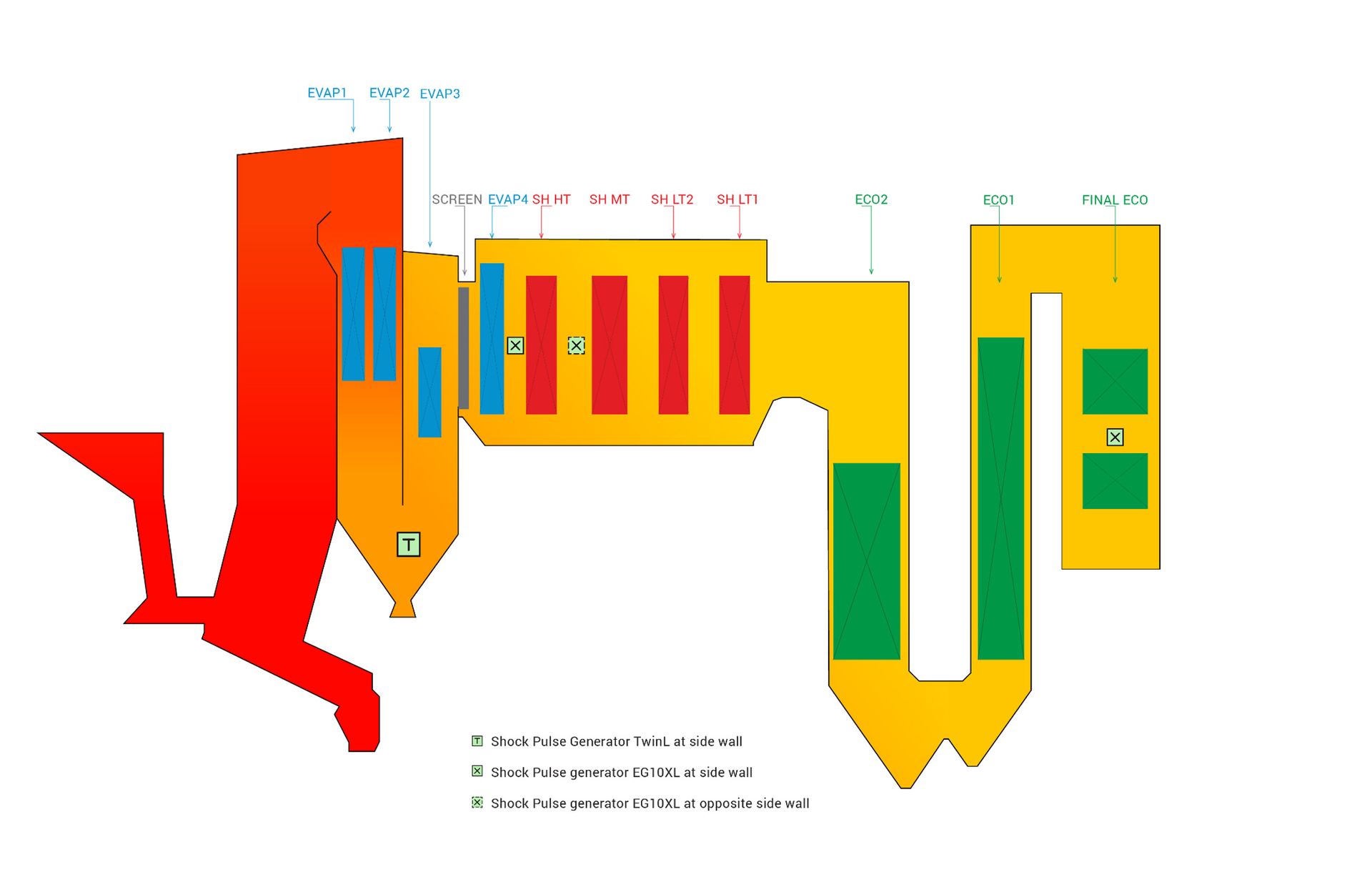

The boiler system, supplied by CNIM, includes:

- Boiler width at Pass 2/3: 9.4 m (with suspended evaporator panels)

- Boiler width at Pass 4: 6.25 m

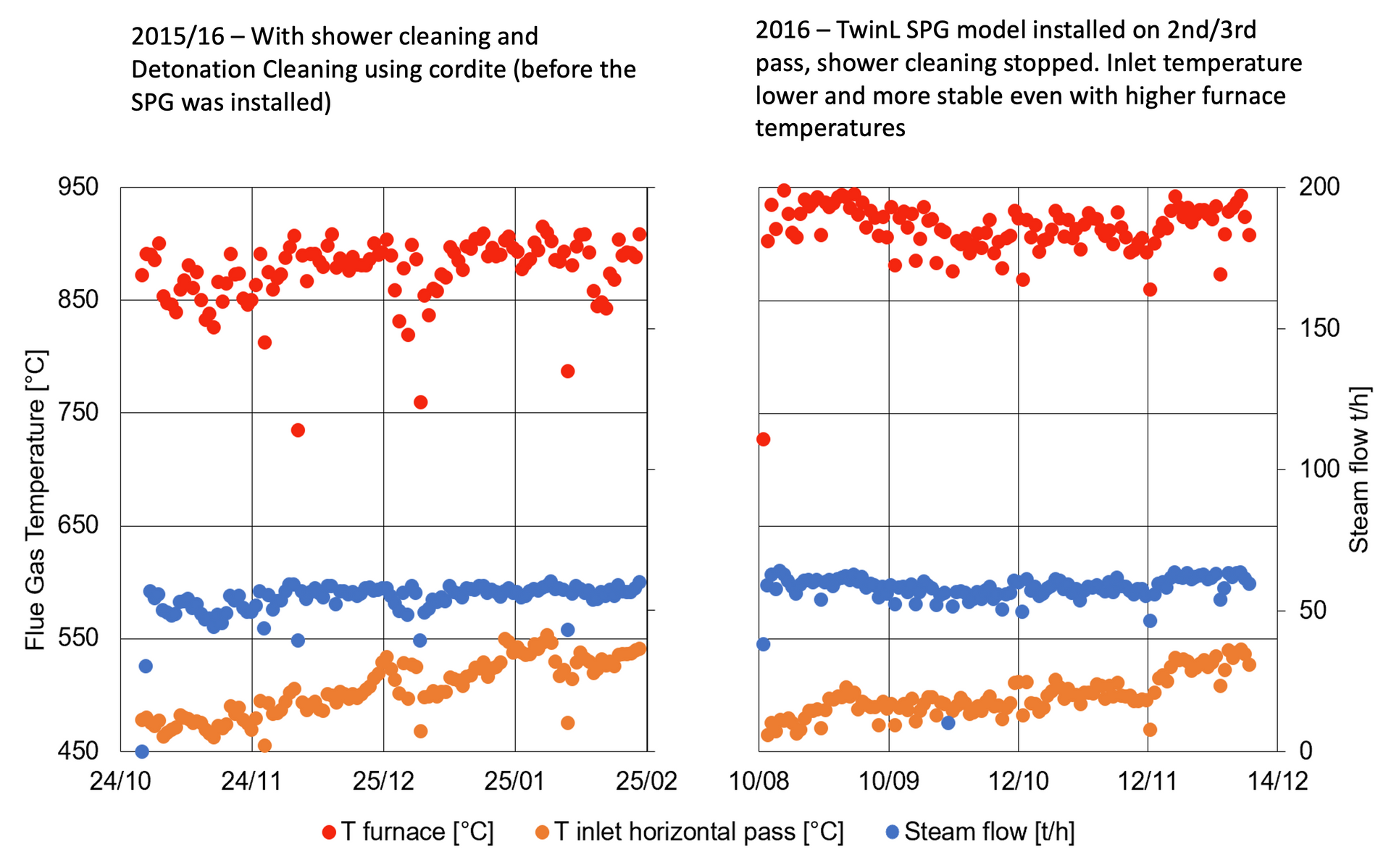

Before SPG installation, the plant was only just achieving its target of 8,000+ operating hours annually. Key fouling hotspots included the 2nd/3rd pass hopper and screen tube sections, which required frequent shower and on-load cleaning using detonation cord. The SPG reduced these disruptions to operations.

Solution: SPG Integration

In August 2016, KRR ProStream installed a TwinL SPG unit at the hopper of the 2nd/3rd pass to address ash accumulation and reduce fouling.

- Unit Installed: 1 x TwinL SPG

- Location: Bottom hopper between Passes 2 and 3

- Operation Cycle:

1 pulse per hour

Key Benefits & Results

Immediately after installation:

- Shower cleaning in the 2nd/3rd pass was eliminated

- Stable temperatures were maintained at the inlet to the 4th pass

- Online detonative cleaning was no longer required, avoiding blockages that previously led to unplanned shutdowns

- Hopper remained clear, with controlled ash flow and no screw feeder trips - previously occurring every six weeks

Additional operational improvements:

- Fouling reduced throughout the boiler

- Superheater attemperator sprays were used less frequently, improving steam cycle efficiency

- The final Comeco economiser now lasts a full 12-month cycle without any intermediate cleaning

- Maintenance periods were shortened, with easier cleaning and less material for disposal

2019 System Expansion

Building on the success of the TwinL unit, FCC Environment expanded SPG use in 2019:

- 2 x EG10XL SPGs were installed between:

- EVAP/SH HT and

- SH HT/SH MT sections

- 1 x EG10XL SPG replaced the rake sootblower between the two Comeco ECO bundles

Strategic impact:

- Rappers, which were previously unreliable, were phased out

- ECO cleanliness improved dramatically

- The plant began targeting 18–24 months between outages - a major leap in performance and reliability

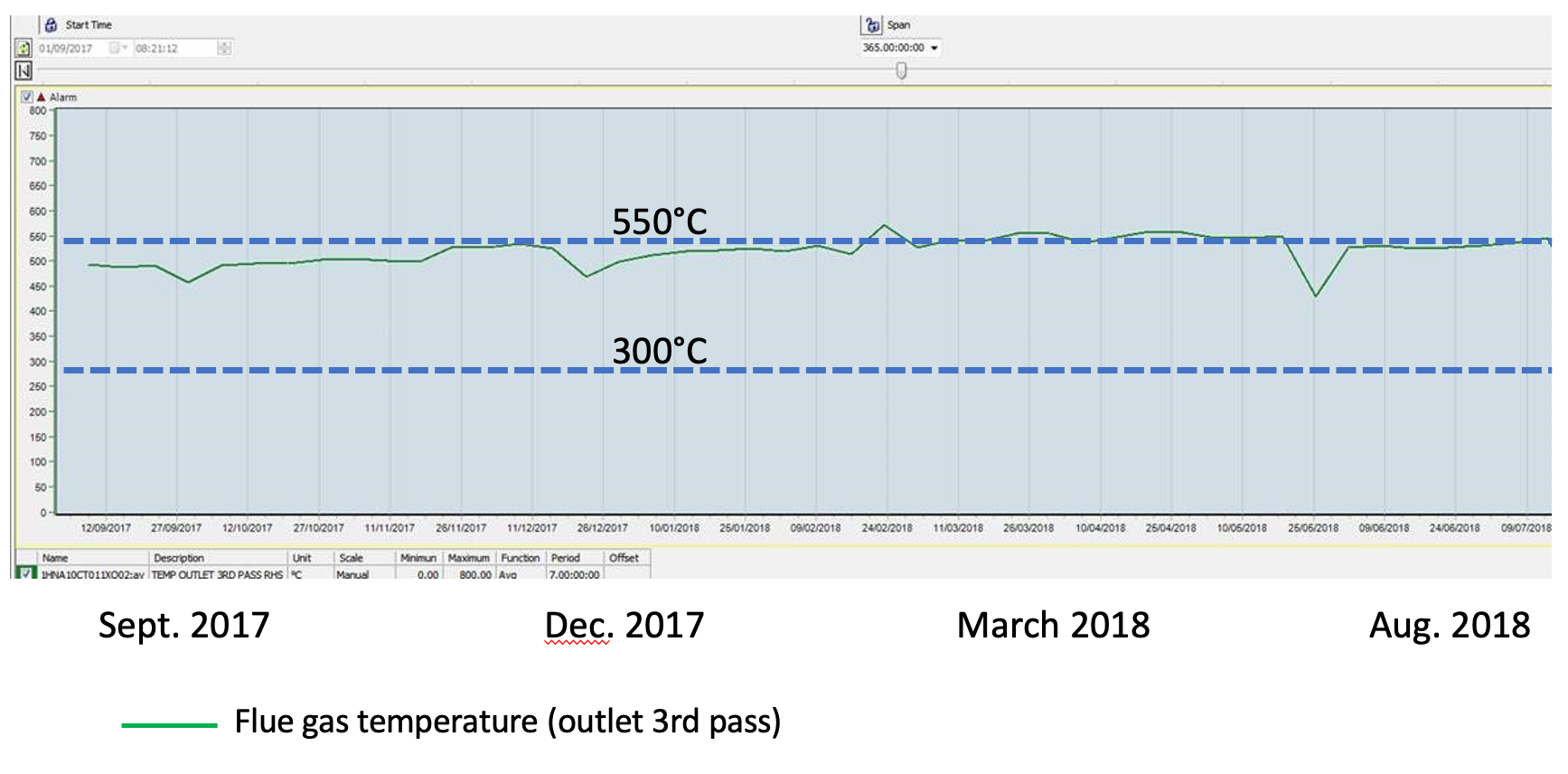

The graph below shows 7 day averaged values for flue gas temperature at the outlet from the 3rd pass. The temperature was controlled at/below approx 550 degrees for the entire operating period with the single TwinL shock pulse generator.

Conclusion

KRR ProStream’s SPG technology has been pivotal in enabling FCC Environment’s facility to meet, and now exceed, its operational targets. The plant has moved from barely achieving 8,000 hours of uptime to building a strategy around 18–24 month outage intervals, all while handling 27% more waste than originally designed.